FlowIO Actuating Miniturised STIFF-FLOP Manipulators

- jialei shi

- May 18, 2023

- 2 min read

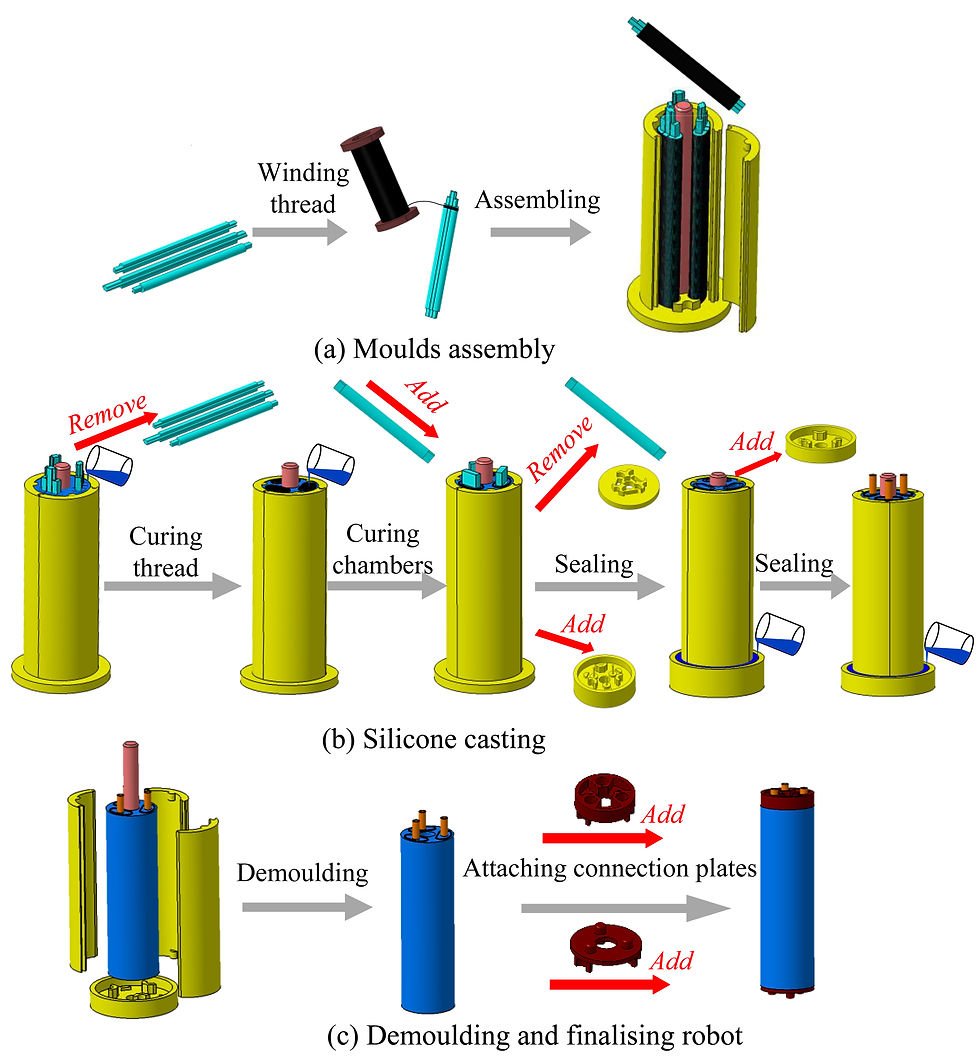

The soft continuum robots are the miniturised STIFF-FLOP manipulators, which are devised for minimally invasive surgery and made of a highly deformable elastomer with a fluidic-driven principle. The robot has individually reinforced circular chambers. Braided in-extensible threads constrain the radial inflation while allowing longitudinal expansion under pressurisation. In this way, the pressurisation does not change the shape and perimeter of all actuation chambers and the strain in the circumferential direction of the reinforcement layer is negligible.

Here, we are demonstrating to use the FlowIO device to actuate such small-scale fibre-reinforced continuum robots, to further develop a portable robotic system for medical applications.

Fabrication process of the robot

Comments